FAST Logistics Group, the leading end-to-end logistics company in the Philippines, explores how technology and innovation bolster cold chain efficiency.

The cold chain industry plays an indispensable role in maintaining the quality and safety of perishable goods. From agricultural produce to pharmaceuticals and frozen foods, cold chain logistics ensures that temperature-sensitive products arrive at their destinations in optimal condition.

However, the traditional methods of managing cold chain operations have proven to be inefficient and costly. Conventional approaches such as manual monitoring and paper-based tracking systems are prone to human error, leading to spoilage, product recalls, and financial losses. This is where technology and innovation play a crucial role.

Logistics professionals and supply chain managers should thus remain informed of technological advancements in cold storage management to enhance efficiency, reliability, and resiliency across the supply chain. By staying updated on the latest technology and innovations in cold chain management, they can take advantage of these modern systems to boost customer satisfaction and ensure the quality and safety of temperature-sensitive goods such as perishable foods and pharmaceutical products.

Technology and Innovations in Cold Chain

Cold storage management in the Philippines is continually evolving, propelled by technology and innovations. Here are the key trends that are reshaping the cold chain industry.

Artificial Intelligence and Machine Learning

Artificial intelligence and machine learning enhance cold chain management by enabling predictive analytics and real-time decision-making. AI algorithms and technologies can analyze historical data to predict potential equipment failures in both warehouse and transport operations for proactive maintenance. This minimizes downtime and ensures product integrity throughout the supply chain.

FAST Logistics Group, the leading end-to-end logistics company in the Philippines, offers intelligent cold chain solutions under its brand, “Fresh by FAST.” Our intelligent ColdChain solutions ensure perishables are kept at the ideal temperature, ensuring they look and feel their best when they reach your customers. Fresh by FAST caters to businesses dealing with fresh products, including meat, poultry, seafood, dairy, processed foods, fruits, vegetables, medicines, and vaccines.

Blockchain Technology

Blockchain technology provides a secure and transparent platform for managing cold chain operations. It creates a permanent record of each step in the supply chain and ensures traceability and verification. This is especially critical in industries like pharmaceuticals and food, where traceability is essential to combat counterfeiting and ensure product safety. By leveraging blockchain, companies can ensure that products are stored and transported under optimal conditions, protecting both consumers and brand integrity.

Centralized Control Monitoring System

Centralized control monitoring systems are used to integrate and transmit data from various sources, providing a comprehensive view of the entire cold chain. This system allows logistics managers and supply chain professionals to have real-time visibility over temperature conditions, equipment performance, and delivery status at any remote location. It also facilitates data-driven decision-making, enabling prompt responses to any issues that arise in the storage and transport of goods such as agricultural products, medicines, and vaccines.

Diversified Cold Storage Capabilities

Diversified temperature storage capabilities enable cold storage facilities to accommodate a wide array of products, each with unique temperature needs. Advanced refrigeration systems with zoned temperature control ensure that different items can be stored together without compromising quality. This flexibility is especially beneficial for businesses managing a diverse portfolio of temperature-sensitive goods.

At FAST, we are your one-stop solution for all temperature-controlled needs. Our services include refrigerated transport, cold storage, blast freezing, processing, and dry warehousing. Our ColdChain Hubs operate at multiple temperature levels — frozen, chilled, ambient, and dry — ensuring your items stay fresh from source to store.

Eutectic Trucks

Eutectic trucks are equipped with eutectic plates or phase change materials that can maintain the required temperature for an extended period, even without a power source. This is a cost-efficient alternative to refrigerated trucks and useful in areas with unreliable electricity supply. It can also be used during long-distance transportation where access to power may be limited. Eutectic trucks ensure that products remain at the desired temperature throughout their journey, eliminating the risk of spoilage and contamination. However, the temperatures inside eutectic trucks drop whenever they are opened. Logistics managers should therefore strategically deploy these trucks for cargo transport with minimal stops and shorter distances.

Internet of Things and Temperature Sensors

The Internet of Things (IoT) and temperature sensors are transforming the way cold storage facilities are managed and monitored. These technologies enable real-time tracking and monitoring of temperature, humidity, and other environmental factors in refrigerated containers, trucks, and warehouses. The data collected from these sensors can be analyzed to identify trends and optimize cooling processes, ensuring the preservation of product quality and safety. This is especially crucial for the transport and storage of perishable foods, vaccines, medications, and infant formula, among other goods that require constant temperatures.

Renewable Energy Sources

Sustainability is a growing concern in the logistics industry. As a solution, cold storage facilities are leveraging renewable energy sources to reduce their carbon emissions and reliance on fossil fuels. Solar panels, wind turbines, and other renewable energy technologies can be used to provide energy requirements and lower operational costs of logistics operations. In the Philippines, where sunlight is abundant, solar energy offers a critical and viable solution for powering cold chain infrastructure. Renewable energy sources also help cold chain facilities lower operational costs in the long run.

FAST ColdChain Hub Cavite can accommodate 13,000 pallet positions, with 10,000 designated for cold storage and 3,000 for dry and air-conditioned storage. About 20% of our facility’s daily energy needs are powered by renewable energy, with our solar panels generating 600 kW.

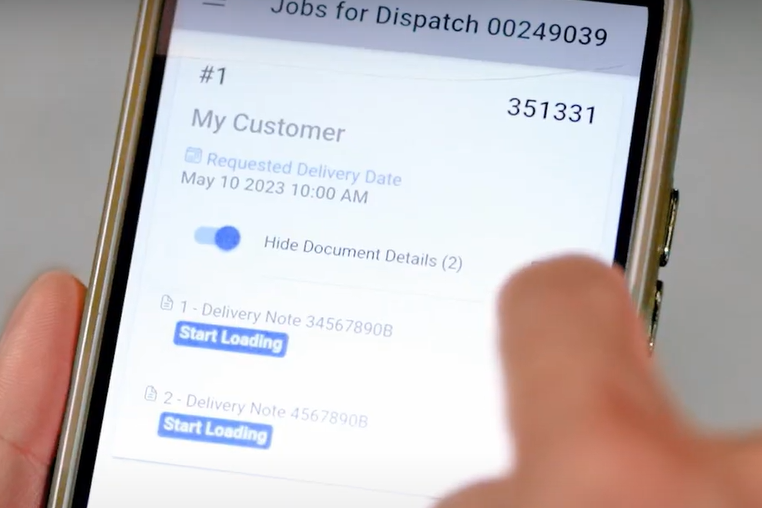

Transport Management System

Innovative transport systems are essential for maintaining the integrity of temperature-sensitive shipments during transit. Transport Management Systems provide real-time visibility of refrigerated trucks and fleet, enabling agile response if any disruption occurs to ensure cargo remains within the required temperature range. These are also used to boost route efficiency and maximize truck load utilization to minimize delays and reach customers faster.

Warehouse Management System

Warehouse Management System benefits businesses as it automates every stage of the warehouse process at cold storage facilities. It is used to efficiently handle inventory, reducing the need for manual labor and minimizing human error. In cold environments, automation also reduces the exposure of workers to extreme temperatures and increases product visibility which enhances workplace safety and productivity.

FAST leverages Warehouse Management System or WMS, powered by Honeywell, in its cold chain operations. WMS is a sophisticated software solution designed to optimize and streamline warehouse operations including inventory management, order processing, picking, packing, and shipping.

Watch the video below to learn more about the benefits of technology and innovation in cold chain management.

Benefits of Technology and Innovation in Cold Chain

The cold chain industry in the Philippines is rapidly evolving due to technological advancements and changing consumer demands. Embracing these trends has become essential for businesses to stay competitive and meet the growing complexities of temperature-controlled supply chains. Here’s how technology and innovation are benefiting these businesses.

Increased Efficiency and Reliability

Cutting-edge technologies such as Warehouse Management Systems and Transport Management Systems are streamlining operations and increasing the efficiency of cold storage facilities. It helps minimize pen-and-paper processes and ensures that products remain at the required temperature throughout their journey. This also reduces spoilage rates, making cold chain processes more reliable. Automation also minimizes labor costs while ensuring accurate handling of inventory and shipments and leading to cost savings in the long run.

In addition, automation brings various benefits to businesses. Advanced systems streamline processes, save time, and reduce operational costs. It also minimizes human intervention, lessens paperwork, and reduces the risk of errors in warehouses and transport operations which enhances overall efficiency. Ultimately, automation allows employees to focus on more strategic tasks, driving innovation and growth within the company.

Improved Temperature Control for Product Safety

Cutting-edge technology such as the Internet of Things and temperature sensors greatly benefit cold chain management by ensuring precise temperature ranges in transport and storage facilities. These advanced systems continuously monitor and record temperature data, providing real-time alerts if conditions deviate from the set parameters.

This level of oversight reduces the risk of spoilage and contamination, which is particularly important for industries like pharmaceuticals and food. In the pharmaceutical industry, maintaining strict temperature control is crucial for the efficacy and safety of medications. Similarly, in the food industry, proper temperature management ensures that products remain fresh and safe for consumption, thereby reducing waste and protecting public health.

Real-Time Tracking, Monitoring, and Response

Technology and innovation provide real-time visibility in cold chain operations. With the help of real-time tracking and monitoring systems, businesses can gain insight into their supply chain processes and make data-driven decisions. This level of visibility helps identify inefficiencies and bottlenecks in the system, enabling businesses to implement improvements for better performance.

Furthermore, real-time tracking enables agile response to disruptions, such as unexpected delays or temperature deviations during transport. By receiving immediate alerts, businesses can take swift action to rectify the situation and minimize any potential risks or damages to their temperature-sensitive products.

Better Decision-Making and Customer Service

Automated systems can handle large volumes of data with ease, ensuring consistency and reliability. These systems can analyze data patterns and provide insights that inform better decision-making processes in cold chain logistics, ultimately ensuring the optimal preservation and transportation of temperature-sensitive products.

In addition, automation can improve customer service by enabling faster response times and more personalized interactions. Automated systems can handle routine inquiries efficiently, allowing human agents to focus on more complex issues. This combination can lead to higher customer satisfaction and loyalty as customers receive timely and tailored support.

More Sustainable Operations

The use of renewable energy sources has become increasingly popular in cold storage operations. Besides reducing carbon emissions and operational costs, integrating renewable energy sources also makes cold chain operations more environmentally sustainable. This aligns with consumers’ growing demand for eco-friendly processes across the supply chain. It is also beneficial for businesses as governments are requiring organizations to adopt sustainable practices and reduce their environmental impact.

Moreover, the use of advanced technology and automation also reduces waste in cold chain processes, resulting in a more sustainable operation overall. With better inventory management and monitoring systems, businesses can reduce spoilage rates and minimize the need for product disposal.

Empowered Workforce

By automating repetitive tasks and providing workers with advanced tools, technology empowers the workforce to focus on higher-value activities across the supply chain. Employees can channel their energy into more strategic and creative aspects of their roles, fostering innovation and problem-solving.

This enhances job satisfaction and productivity, contributing to a more efficient and motivated team. With the reduction in repetitive tasks, employees have more time to acquire new skills and engage in continuous learning, making them more versatile and valuable to the organization. This holistic approach not only boosts the overall performance of the company but also cultivates a culture of growth and resilience in cold chain operations.

Scalable Operations

Innovative technologies enable cold chain systems to scale efficiently, accommodating growing demand without compromising on quality. This scalability is crucial for businesses looking to expand their operations and enter new markets. By leveraging automation and advanced logistics solutions, businesses can maintain control over their supply chain processes while expanding their reach.

Moreover, the integration of cutting-edge technology allows for real-time data analysis and decision-making, enabling businesses to adapt swiftly to market changes and industry trends. It helps in identifying potential inefficiencies and opportunities for improvement and growth.

Cost-Efficiency and Business Growth

The cold chain industry is continually evolving with the advent of technology and automation, becoming more efficient, reliable, profitable, and sustainable. By embracing these innovations, businesses can stay ahead of the curve, meet the shifting demands of consumers and regulations, and drive growth and innovation within their operations.

To stay relevant in the dynamic field of cold chain logistics, businesses should keep up with these trends and invest in advanced technologies. Watch the video below to discover how our partners at PandaMart benefit from our innovative and tech-forward cold chain solutions.

With our ColdChain Hubs in Cavite and North Cebu now operational, FAST boasts a cold chain footprint of 30,000 pallets, ready to meet all your cold storage needs. Customers pay only per pallet, and our facility guarantees each product is protected from allergens, odors, and chemicals.

Leveraging New Technologies for Cold Chain Efficiency in the Philippines

As technology continues to evolve, cold chain management will become more efficient, effective, sustainable, and reliable. For logistics professionals, supply chain managers, and businesses in the Philippines, staying ahead of these advancements is crucial for maintaining a competitive edge.

With a focus on innovation, FAST Logistics Group remains committed to leveraging technological advancements in cold chain management to deliver exceptional solutions and exceed customer expectations. By embracing these technologies, we aim to provide integrated, intelligent, and flexible end-to-end cold chain solutions for our customers in the business of fresh.

As the leading end-to-end logistics company in the Philippines, FAST leverages advanced technologies to optimize our cold chain operations and ensure all temperature-controlled storage requirements are met efficiently. We help businesses and companies deliver superior products to consumers.

Whether you aim to improve temperature control, reduce costs, or enhance supply chain transparency, the future of cold chain logistics is promising and driven by innovation. Start exploring these technologies today and take your business to the next level. Connect with our Solutions Experts or visit http://linktr.ee/fastlogisticsph to learn more about our cold chain capabilities.

Categories

-

FAST Ahead

Includes case studies and testimonials of our partners as well as other featurettes from industry experts

-

FAST Hacks

We simplify logistics terms and provide practical tips and solutions for the DIY in you

-

FAST Highlights

Know more about our history, various brands, achievements, and news updates

-

FAST Moments

Get to know the people of FAST, our employee programs, as well as our various ways of giving back to the community

-

FAST Solutions

Learn more about the various logistics solutions that we cater to and offer our clients, as well as tech innovations, and service facilities