In today’s fast-paced retail environment, the expectation for instant availability is higher than ever.

Customers demand immediate access to products, and any failure to meet this demand can lead to lost sales and customer dissatisfaction. This is a significant challenge for retailers and sari-sari store owners, who must balance maintaining sufficient stock levels without overburdening their inventory and incurring increased operational costs.

Store owners and retailers can avoid stockouts by adopting innovative strategies and solutions to improve their inventory management, fulfill customer orders, and ensure timely delivery of highly valued products. After all, avoiding stockouts has become a crucial aspect of retail management to ensure business profitability and meet customer demand.

FAST Logistics Group, the leading end-to-end logistics and selling and distribution company in the Philippines, explores ways on how retailers can avoid stockouts and, in turn, dissatisfied customers.

Causes of Stockouts

Stockouts occur when inventory levels are insufficient to meet customer demand. Several factors can lead to stockouts, including the following.

Unreliable Demand Forecasting

One of the primary reasons for stockouts is inaccurate demand forecasting and inadequate planning. When predictions about future sales are off, stock levels either exceed or fall short of actual demand. Overestimating demand leads to excess inventory while underestimating it causes stockouts.

Inaccurate Inventory Counts

Poor inventory management often leads to stockouts, whether due to delayed reordering or the absence of a systematic way to track inventory levels. When businesses fail to reorder products on time, they risk depleting stock before new supplies arrive. Likewise, retailers without an organized method to monitor inventory lack accurate insights into their stock levels which leads to overstocking or understocking.

Employee Errors

Human errors, such as incorrect data entry or misplaced stock, can also lead to stockouts. These mistakes might stem from a lack of training, fatigue, or simple oversight. Regular training sessions to keep employees updated on best practices for managing inventory can significantly minimize these errors.

Shrinkage

Shrinkage, the loss of inventory due to theft, damage, or administrative errors, can result in stockouts by reducing available stock levels unexpectedly. Inaccurate inventory counts may give businesses a false sense of having adequate products, leading to unexpected shortages when customer demand arises.

Limited Shelf Space

Limited shelf space restricts the quantity of products that can be displayed and stored, forcing retailers to make frequent restocking decisions that may not align with demand. When popular items are quickly depleted and there is insufficient space to store products, retailers may face delays in replenishing shelves, resulting in temporary unavailability of products.

Supplier Issues

Late deliveries, vehicle breakdowns, inaccurate records, miscommunication, and other supplier issues can prevent retailers from replenishing inventory on time. In addition, quality control problems from suppliers can result in receiving unusable goods, further exacerbating stockout situations and impacting sales and customer satisfaction.

FAST is the leading selling and distribution partner of top brands in the Philippines. Leveraging its vast network, extensive resources, and dedicated workforce, it empowers businesses to focus on their core operations and maintain market leadership. FAST is adept at navigating the unique challenges of selling and distribution, ensuring products remain affordable even in remote provinces. Supermarkets, retailers, restaurants, eateries, and sari-sari stores in both urban and rural areas rely on FAST to deliver products that customers truly value.

Lead Time Variability

Variability in delivery lead times creates uncertainty in inventory replenishment. These uncertainties challenge retailers to maintain optimal stock levels, often resulting in either overstocking, which ties up capital and storage space, or understocking, which can lead to frustrated and dissatisfied customers.

Supply Chain Disruptions

Supply chain disruptions can wreak havoc on inventory levels. Natural disasters, logistics issues, lack of raw materials, manufacturing delays, political unrest, or even global pandemics can cause delays in deliveries and product distribution. These unforeseen circumstances complicate inventory management, making it challenging to maintain optimal stock levels.

Seasonal Demand Fluctuations

Seasonal trends can also catch retailers off guard. Increased demand during holidays can lead to stockouts if not appropriately planned for. Retailers must anticipate these peaks and ensure they have sufficient inventory to meet customer needs.

Sari-sari store owners benefit from selling and distribution companies that can help them ensure they do not run out of stock of products sold at affordable prices, allowing them to meet consumer demands. FAST ensures that sari-sari stores in the Philippines have a wide range of sachet products so these can provide easy access to daily essentials for local communities. The synergy between FAST and sari-sari store owners creates a robust and sustainable selling and distribution model that benefits various companies and Filipino consumers.

Best Strategies to Avoid Stockouts

Retailers should implement various strategies to maintain adequate stock levels and meet customer demand. Here are some ways to ensure optimal inventory levels.

Accurate Demand Forecasting

Accurate demand forecasting is the first step to preventing stockouts. Retailers may use historical sales data, market trends, and advanced analytics to predict future demand more accurately. Shops with a well-implemented forecasting system can store high-demand items and avoid overstocking on less popular products.

Regular Inventory Audits

Market trends and customer preferences change over time. Effective inventory management strategies such as regular inventory audits enable store owners to identify high-demand products, low-demand items, and their reorder needs, thus preventing stockouts and erroneous forecasts. Through accurate records, retailers can make informed decisions about purchasing, pricing, and promotions for their inventory levels and boost overall profitability.

Employee Training

To reduce stockouts caused by human error, such as incorrect data entry or misplaced stock, implementing regular training sessions is crucial. These sessions should focus on best practices for inventory management. Retailers may also incorporate automated systems for data entry and stock tracking further minimize the risk of mistakes.

FAST employs salesmen who possess deep knowledge of Philippine provinces and work tirelessly to ensure timely and efficient distribution of products. FAST also leverages multiple sales channels and methods to cater to diverse Filipino shopping habits across different regions and even in remote provinces. Each department within FAST works cohesively to successfully bridge the gap between manufacturers and retailers.

Update Monitoring Systems and Security Controls

Store owners can reduce shrinkage by upgrading their monitoring systems and enhancing security measures. Furthermore, implementing damage control protocols ensures proper handling and storage of inventory and minimizing lost sales. Combined, these strategies will help maintain accurate inventory counts and prevent unexpected stockouts.

Maximize Use of Available Space

Integrating space-saving storage solutions can significantly maximize the use of available space in any storage area. This helps organize products more effectively and ensures that inventory is visible and accessible. In addition, a well-organized space leads to a more efficient restocking process, as store employees can quickly locate and replenish items.

Diversified Supplier Base

Relying on a single supplier is risky. Retailers should partner with various suppliers to ensure that they have multiple sources of products for their inventory needs. This also allows store owners to negotiate better pricing and terms with suppliers. A diversified supplier base also enables retailers to access a broader range of products and alternative items, thus enhancing their cross-selling abilities.

Collaborative Planning with Suppliers

When suppliers and distributors across the supply chain have a thorough understanding of retailers’ needs, they can better provide more efficient services, delivery schedules, and lead times to ensure product availability. Effective communication and sharing sales data with suppliers can help them plan better and deliver on time, thereby reducing the risk of potential stockouts or overstock situations. In addition, regularly updating distribution partners on upcoming promotions or changes in demand can further enhance their ability to support businesses.

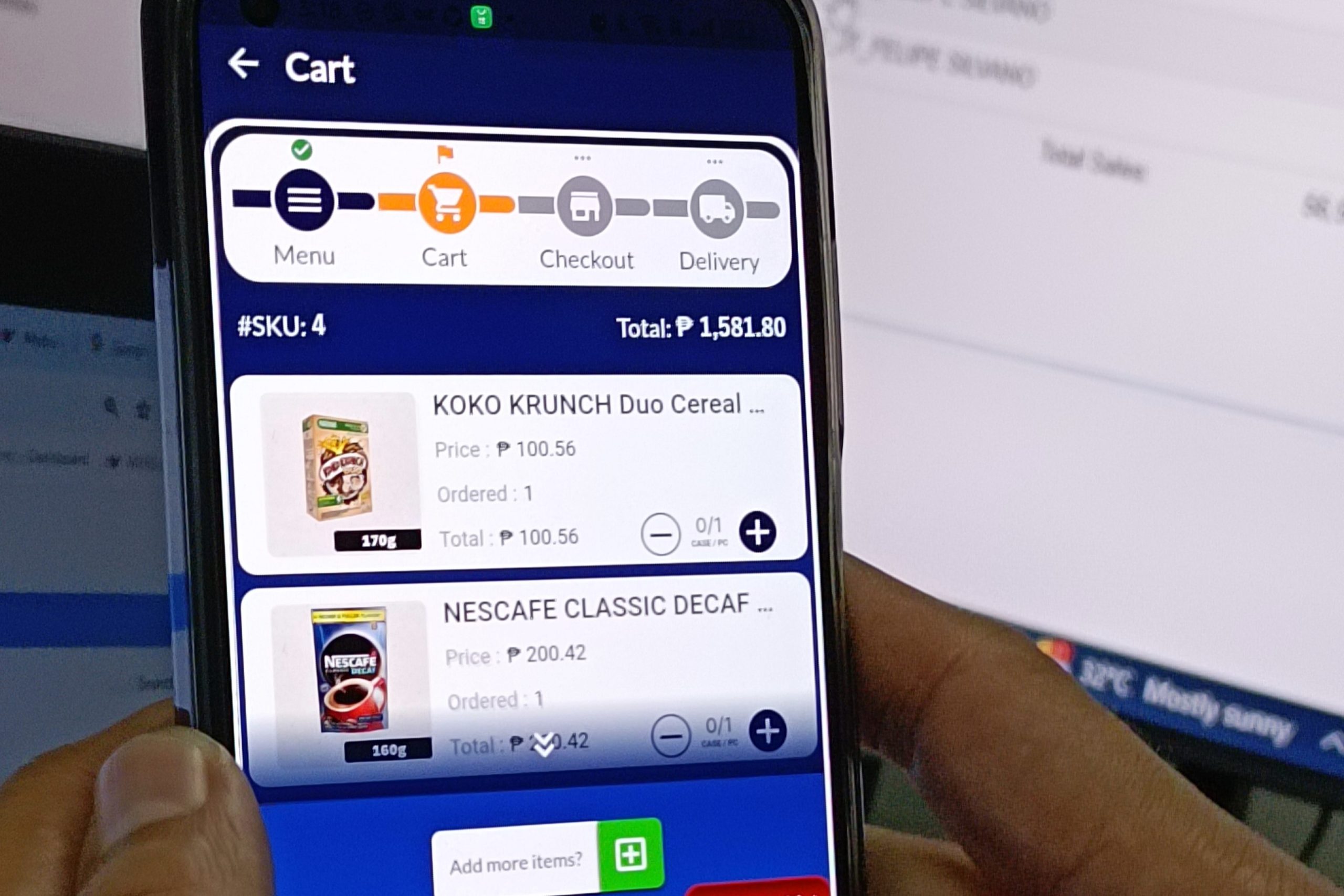

FAST leverages sales force automation tools to maximize the sales efficiency of its team. Among these tools is the MyBuddy app, which enables FAST’s sales representatives to efficiently record and process orders from sari-sari store owners.

Optimizing Lead Time

Work closely with suppliers to optimize lead times. Faster delivery times mean you can reorder stock more frequently, reducing the likelihood of stockouts and ensuring that your customers always have access to the products they need. Retailers may also consider leveraging technology to track shipments and anticipate potential delays, enabling proactive adjustments to their inventory management strategy.

Securing Safety Stock

Retailers should maintain a safety stock or a small surplus of inventory which can act as a buffer against unexpected demand spikes or supply chain disruptions. Safety stock levels can vary based on the type of product, industry, and lead time for suppliers. It is important to regularly review safety stock levels to ensure they are appropriate for the needs of small businesses. Ordering seasonal stock also helps retailers prepare for peak demand periods and avoid stockouts.

Product Diversification

Diversifying your product range can also help in avoiding stockouts. Offering a variety of products ensures that even if one item is out of stock, customers have other options to choose from. This not only helps in retaining customer retention but also enhances their shopping experience by providing them with a wider selection. Furthermore, a diverse product range can attract a broader customer base and cater to different needs and preferences, thereby boosting overall sales and customer satisfaction.

Awareness of Customer Trends

Retailers should maintain open communication with customers and be adept at customer trends. Knowledge about consumer behavior and preferences will serve as a guide on which products should be kept at high volume. Inventory levels should also be adjusted regularly according to seasonal trends to ensure the availability of high-demand items during peak times.

FAST also utilizes Sosyo by FAST, a business intelligence tool designed for store owners and retailers to easily order products. This mobile app simplifies product ordering, akin to popular e-commerce platforms, allowing store partners to effortlessly select desired products, quantities, and delivery dates. It can be downloaded for free on the Google Play Store for free.

Automated Reordering

Store owners can leverage digital tools that make the ordering process simple and efficient. These tools not only automate the reordering of stock but also provide real-time insights into inventory levels. This makes it easier for them to maintain product availability, avoid stockouts, and enhance overall operational efficiency.

Benefits of Stock Availability

Ensuring stock availability is crucial for any business. Here’s how it impacts profitability and customer experience.

Increased Sales and Revenue

When products are consistently available in retail stores, customers are more inclined to make purchases promptly and without frustration. Satisfied customers are also more likely to return and recommend your business to others, thereby increasing sales and revenue potential.

Enhanced Customer Satisfaction

Nothing frustrates a customer more than finding an empty shelf where their desired product should be. It can lead to disappointment and a negative perception of the store. Conversely, a well-stocked shelf also shows that the store is reliable and attentive to customer needs. Keeping shelves stocked not only enhances customer satisfaction but also builds brand loyalty.

Competitive Advantage

Retailers who manage to keep their shelves consistently stocked have a significant competitive advantage over those who frequently experience stockouts. Ensuring that products are always available not only prevents lost sales but also builds customer loyalty. When shoppers can reliably find what they need, they are more likely to view the store as their go-to destination.

Watch the video below to learn more about our innovative solutions.

Maintaining Product Availability for Business Success

As consumer expectations continue to rise, finding effective solutions to prevent stockouts has become more important than ever. In a highly competitive market, meeting customer demand consistently can set a retailer apart from its competitors, ensuring both customer loyalty and business success.

Effective inventory management strategies such as real-time stock monitoring, collaborating with selling and distribution partners, and securing safety stocks, among others, can help prevent stockouts. Aside from customer satisfaction, these practices also contribute to increased sales and a competitive edge in the market. Retailers should therefore continue refining their practices to maintain the availability of products and keep up with customer demands.

As an industry leader and trusted partner for selling and distribution of major brands in the Philippines, FAST ensures that retailers and store owners have the support and resources they need to meet consumer demand and achieve long-term success. Leveraging its deep understanding of the local market, diverse selling and distribution strategies, advanced systems and tools, and a dedicated workforce, FAST makes valuable products and preferred brands affordable, accessible, and available in retail stores nationwide.

Businesses in the Philippines should take advantage of FAST’s capabilities and solutions in selling and distribution for sustained growth and success. To learn more about us, contact our Solutions Experts or visit http://linktr.ee/fastlogisticsph today

Categories

-

FAST Ahead

Includes case studies and testimonials of our partners as well as other featurettes from industry experts

-

FAST Hacks

We simplify logistics terms and provide practical tips and solutions for the DIY in you

-

FAST Highlights

Know more about our history, various brands, achievements, and news updates

-

FAST Moments

Get to know the people of FAST, our employee programs, as well as our various ways of giving back to the community

-

FAST Solutions

Learn more about the various logistics solutions that we cater to and offer our clients, as well as tech innovations, and service facilities